PAT-L MicroNIR spectrometer

Process monitoring for liquid analysis

- compact

- real time analysis

- all in one optic design

The newest instrument in the MicroNIR PAT line, the PAT-L spectrometer uses NIR (near infrared) spectrometry to perform non-destructive analysis and provides real-time results for continuous process monitoring in liquid, aqueous and organic industries. It is rugged and ultra-compact, easily integrated into industrial facilities (tanks and pipelines) and requires little maintenance. PAT-L consists of the PAT-U MicroNIR spectrometer and a customizable probe that is immersed in the liquid to be analyzed.

Advantages

Designed for regulated industries

MicroNIR PAT-L has been specifically designed to allow the analysis of liquids in the most strictly regulated industries, such as pharmaceutical/cosmetic, food and beverage, fine chemicals, and ATEX facilities. PAT-L operates without fiber optics to limit operating costs. And the tungsten lamp allows for long term use and requires no maintenance.

Customizable probe

The MicroNIR PAT-L probe is customizable, depending on

- probe material (316 L or Hastelloy C-22)

- optical path length (2, 3, 4, 5, 10 mm)

- immersion depth (100 – 900 mm)

- process connection

- removable cooling jacket

Applications

Pharmaceuticals

Continuous control of manufacturing processes for liquid and aqueous

Chemical

Polymerization monitoring

Oil & Gaz

Octane number, properties and identification of fuels and lubricants

Specifications

| Technology | NIR (near infrared) |

| Spectral range | 950 - 1650 nm |

| Resolution | 1.25% |

| Signal to noise ratio | 1 : 23 000 |

| Connexion | 3m USB cable |

| External diameter | 26 mm |

| Optic window | Saphir |

| Operating conditions | -30°C to 400°C |

| Maximum immersion depths | 240, 440, 640, 940 mm |

| Optical path length | 2, 3, 4, 5, 10 mm |

| Materials of the probe body | Stainless steel 316L, Hastelloy C22 |

| Process connections (without flange) EN 1092-1/05/A | DN40/PN40, DN50/PN16 or /PN40, DN80/PN16 or /PN40 |

| Process connections (without flange) ASME B16.5 | NPS 1.5 Class 150 or 300 RF, NPS 2 Class 150 or 300 RF |

| Seals | High nickel alloy C-ring, gold plated. |

| Gas filling | N2, 4 bar |

| Maximum pressure rating | 10, 16, 40, 160, 250 bar |

| IP rating | IP65, IP67 |

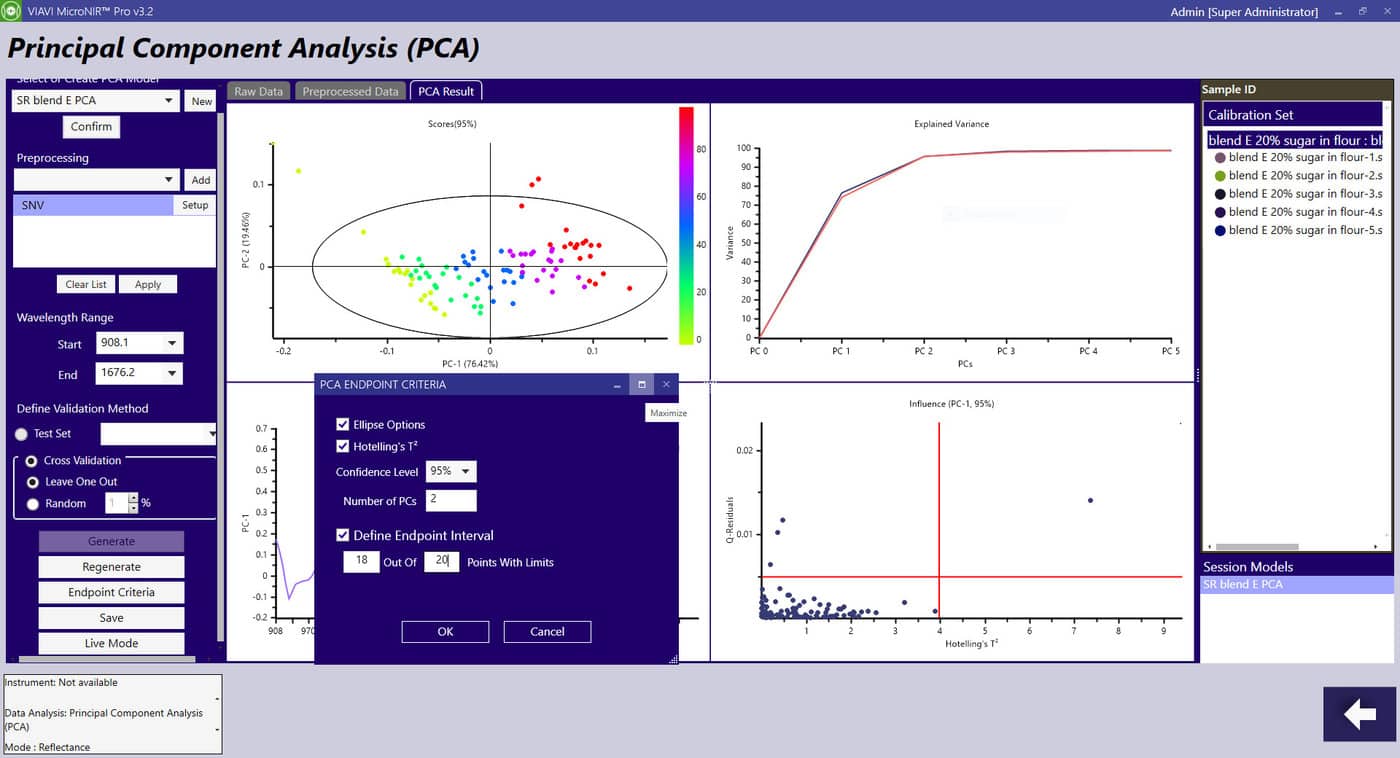

Software

The MicroNIR Pro software suite includes functionality for data acquisition, calibration and method development, user management and real-time prediction. MicroNIR Pro can create and apply comprehensive chemometric models using regression and classification algorithms, including PLS, Moving Block, SMV and PCA analyses. Batch mode predictions on stored data are also supported. Options include an enhanced OPC interface for integration with process control systems and prediction engine add-ons.