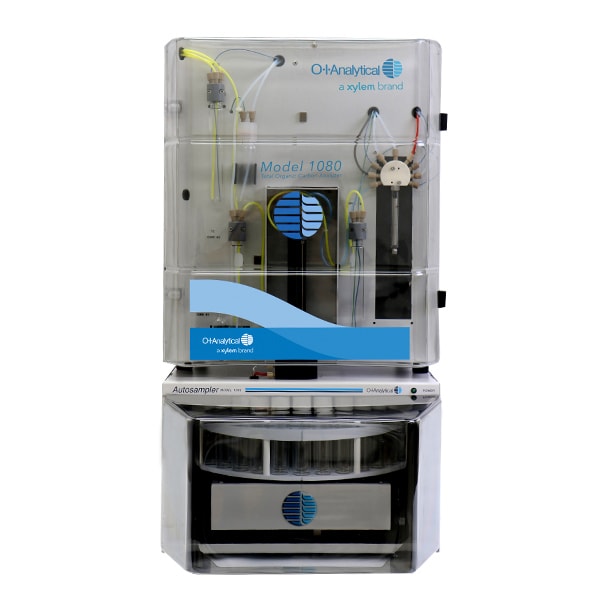

Aurora 1080 TOC Analyzer

TOC analyzer

- Easy to use

- Accurate

- Performant

The Aurora 1080 is a benchtop TOC analyzer for the quantification of Total Organic Carbon (TOC) for water quality monitoring. With its high temperature (680°C) catalytic combustion technology, the Aurora 1080 is an ideal measurement tool for analyzing wastewater, wastewater treatment plants, industrial wastewater, seawater, drinking water and groundwater. Its performance allows laboratories to optimize and automate certain analyses and its design has been thought to reduce maintenance operations, to gain productivity even in a rigorously regulated environment.

Advantages

Patented innovations

- Smart slide injector: Reduced maintenance frequency due to a longer life of the seal.

- Pulsed time injection: Reduction of the vaporization time in the furnace by introducing large volumes of samples in several micro-injections.

- Tube guard protector: Recovery of non-combustible salts and optimization of the longevity of the platinum catalyst.

- Stop flow – bypass injection : Conversion of the combustion tube into a CO2 trap for a better resolution of the peaks at the detector.

Increase productivity

With an analysis time of less than 5 minutes and a throughput of up to 300 samples per day. The Aurora 1080 TOC Analyzer provides laboratories with a significant productivity boost. The TOC 1080 has an autosampler for 88 samples. Sample agitation is performed with a magnet bar. Sample dilution is automatic. It is also possible to add samples during the analysis.

Applications

Pharmaceuticals

Specifications

| Method compliance | USEPA, CEN, USP, EUP, ASTM, ISO, DIN, STD methods |

| Measurement range (ppm) | 50 ppb C – 2,000 ppm C |

| Method TC | 680 °C with platinum catalyst |

| Method TIC | Acidifi cation and sparging |

| Method TOC | NPOC, combustion of TIC-free sample, TOC by subtraction (TC–TIC) |

| Furnace temperature | Adjustable, 680 °C in 1°C increments; 720 °C for TNb |

| Measuring time | From three minutes |

| Oxidation technique | High temperature catalytic oxidation, liquid samples |

| Options available | TNb |

| Reproducibility | 3.0% |

| Accuracy | +2% FS or 2% relative |

| Sample pathway | Color-coded Tefl on® and PEEK® with automatic cleaning in all injection modes |

| Sample injection and sample handling | Injection: sipper, rotary autosampler Handling: automatic syringe with sliding TC furnace injector |

| Sample injection volume | 50 μL – 2.0 mL in 10 μL increments |

| IC pretreatment | Available with autosampler |

| Certifications | CE; EMC: Directive 2014/30/EU; Safety: LVD 2014/35/EU; RoHS: Directive 2011/65/EU |

| Operation mode | Controlled via PC software (Windows 7, 8, 10 PRO) |

| Operating interface | Windows PC |

| Software (included) | Multi-instrument control via PC-based software; LIMS operation, data management, custom reports |

| Operating System | Windows® 7 (with Service Pack 1 or higher), Windows® 8, 8.1 & 10 |

| Reagent purge | Yes |

| Reagents required | Hydrochloric acid, rinse water |

| Communications | USB-to-RS422 communications cable (5m length) |

| Input and output relays | Two user-programmable inputs, two user-programmable outputs |

| Ambient temperature range | 10 °C – 37 °C |

| Operating humidity | <90% noncondensing |

| Power Requirements | 115/230V AC, 50/60 Hz, 750VA max |

| Benchspace with autosampler | L 35.6 x D 48.3 cm |

| Gas type and grade | Oxygen or Air, 99.995% (carbon dioxide and hydrocarbon free), 50-60 psig |

| Dimensions | H 74 x W 36 cm x D 48 cm |

| Weight | 17.5 kg or 37.5 kg with autosampler option |

| Warranty | 12 months on parts and labor |

Software

TOC View software enables fully automated data collection, analysis, reporting and storage in a LIMS environment using a logical and easy-to-follow layout.

- Create methods for analysis of a wide variety of samples

- Easy configuration of priority samples

- Automated routine checks and tests

- Calibration method setup

- Report generation