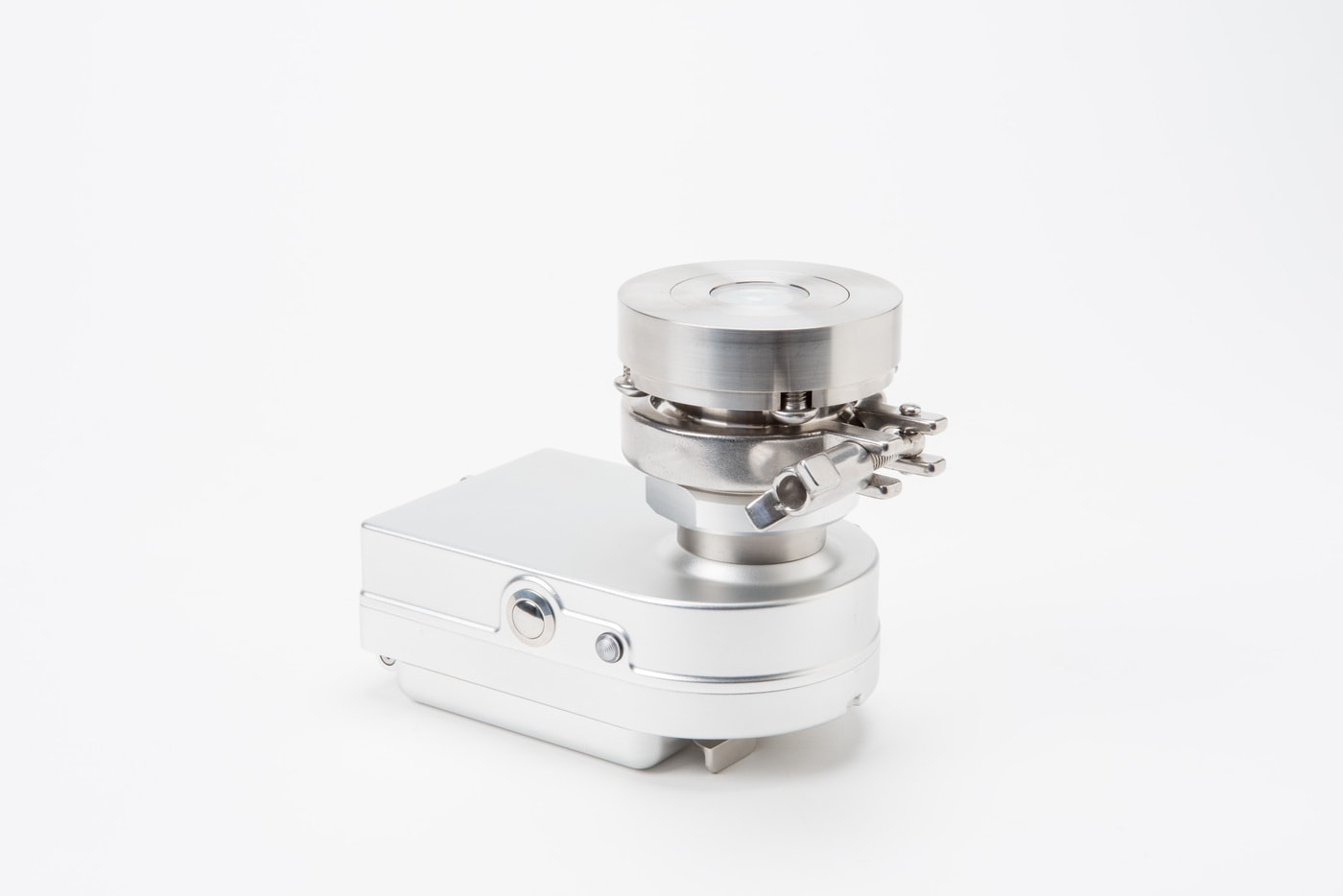

PAT-W MicroNIR Spectrometer

Continuous process control

- compact

- intégratable

- real time results

MicroNIR PAT-W is a NIR (near infrared) spectrometer. A rugged and scalable wireless system used for real-time monitoring of manufacturing processes such as blend homogeneity, uniformity, drying loss, roll compaction and similar applications. Its Linear Variable Filter (LVF) technology makes the PAT-W an ultra-compact, high-performance sensor that integrates directly with process equipment to facilitate efficient and intelligent manufacturing (QbD).

Designed to handle harsh GMP-regulated environments, the PAT-U spectrometer requires minimal maintenance. There are no expensive fiber optic cables or moving components, allowing for superior stability and performance in complex environments.

Advantages

Compliance for regulated environments

Designed to be integrated into harsh GMP regulated environments, the PAT-U spectrometer requires minimal maintenance. There are no expensive fiber optic cables or moving components, allowing for superior stability and performance in complex environments.

Standard mounting

This integration requires a weld in the flange, a sanitary flange bracket, a sapphire window and a retaining ring with O-rings. The flange is welded into a hole cut in the mixer cover, then the sanitary flange bracket, window and retaining ring are assembled. Then the PAT-W is secured against the window and a sanitary flange with a standard tri-clamp (or C-clamp). All parts can be removed for easy cleaning and maintenance.

Threaded mounting

The threaded mount allows a user to weld a mount into the processing equipment and then connect the PAT-W using the threaded tip of the spectrometer. This mount also has a removable window to allow for easy cleaning and maintenance. The PAT-W has a built-in 9-axis inertial measurement unit (IMU), which allows accurate and repeatable triggering of spectral acquisition when the PAT-W is mounted on a rotary mixer.

Applications

Pharmaceutical

Monitoring of mixtures (granulation, drying, uniformity)

Feed & food industry

Quality control (moisture content, protein, fiber, etc.)

Industry

Polymers, reaction monitoring, petrochemicals

Specifications

| Technology | NIR (near infrared) |

| Illumination source | Two integrated vacuum tungsten lamps |

| Bulb life | >40,000 hours |

| Illumination geometry | Flood illumination/ 0° observer |

| Input aperture dimensions | 2.5 x 3.0 mm |

| Sample working distance | 0-15 mm from window |

| Dispersing element | Linear variable filter (LVF) |

| Detector | 128-pixel InGaAs photodiode array |

| Pixel size/pitch | 30 µm x 250 µm/50 µm |

| Wavelength range | 950 – 1650 nm (10,526 – 6060 cm-1) |

| Pixel-to-pixel interval | 6.2 nm for 950-1650 nm |

| Spectral bandwidth (FWHM) | <1.25% of center wavelength (1% typical) (for example, @1000 nm, resolution is <12.5 nm) |

| Analog-to-digital Convertor | 16 bit |

| Dynamic range (max) | 1000:1 |

| Measurement time (typical) | 0.25 – 0.5 second |

| Integration time | 10 ms typical, minimum 10 µsec, maximum limited by dark signal |

| Computer interface | TCP/IP Cat5 Ethernet 802.11 g WiFi |

| Size | 160 mm x 136 mm x 136 mm |

| Weight | < 1.4 kg |

| Power | Rechargeable lithium-ion battery 7.5 V @6.4 Ah for >8 hr run time External: 110-240 V AC |

| Data format | Encrypted, Unsb, CSV, and SPC output |

| OS | Windows 8.1, 8, and 7 |

| Software | MicroNIR PAT, Unscrambler X Lite, MicroNIR Process |

| Operating temperature | 0 – 40 deg C (non-condensing) |

| Enclosure | Stainless steel and aluminum: dust and waterproof, sealed and cleanable to IP67 standard |

| Trigger | Internal 9-axis IMU, external 24 V input |

| Mounting | Adaptable stainless steel tri-clover mount |

| Compliance | 21 CFR part 11, ATEX, USP 1119, Ph. Eur. 2.2.40 |